Laser Cutting Thickness Choosing Guide

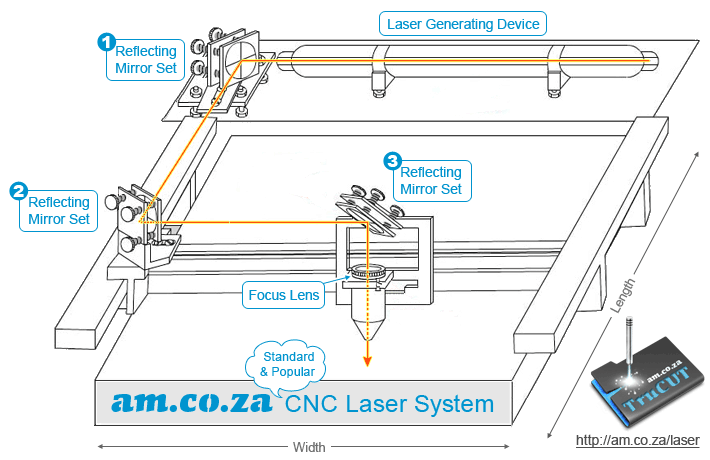

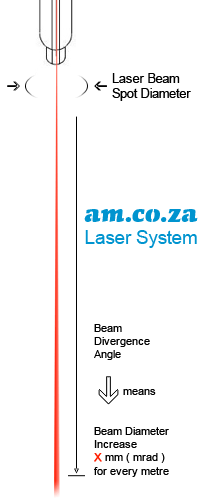

There is no simple answer on the thickness a laser system can cut. http://am.co.za/ Since a laser is a light, it will lose power on propagation and reflection, and tends to be more complex when the machine size is larger. http://am.co.za/ So we have compiled this guide for the laser system that we sell, which gives you a good idea of all kinds of materials that a laser can mark, engrave, drill and cut from the commercially available options that we provide.

Laser Generating Device We Sell ( Laser Tube Warranty )

We only use and sell top glass laser device with outstanding technical parameters for top performance.

| SKU | CO2 Laser System | Rated Power http://am.co.za/ | Max Burst Power http://am.co.za/ | Beam Divergence Angle http://am.co.za/ | Beam Quality ( M2 ) | Spot Diameter |

|---|---|---|---|---|---|---|

| LC-TUBE/30 | TruCUT Standard 30W | lc_tube_30,x_power W http://am.co.za/ | lc_tube_30,x_power_max W http://am.co.za/ | lc_tube_30,x_divergence mrad http://am.co.za/ | lc_tube_30,x_m2 http://am.co.za/ | lc_tube_30,x_diameter mm ±1mm |

| LC-TUBE/40 | TruCUT Standard 40W | lc_tube_40,x_power W http://am.co.za/ | lc_tube_40,x_power_max W http://am.co.za/ | lc_tube_40,x_divergence mrad http://am.co.za/ | lc_tube_40,x_m2 http://am.co.za/ | lc_tube_40,x_diameter mm ±1mm |

| LC-TUBE/60 | TruCUT Standard 60W | lc_tube_60,x_power W http://am.co.za/ | lc_tube_60,x_power_max W http://am.co.za/ | lc_tube_60,x_divergence mrad http://am.co.za/ | lc_tube_60,x_m2 http://am.co.za/ | lc_tube_60,x_diameter mm ±1mm |

| LC-TUBE/80 | TruCUT Standard 80W | lc_tube_80,x_power W http://am.co.za/ | lc_tube_80,x_power_max W http://am.co.za/ | lc_tube_80,x_divergence mrad http://am.co.za/ | lc_tube_80,x_m2 http://am.co.za/ | lc_tube_80,x_diameter mm ±1mm |

| LC-TUBE/100 | TruCUT Standard 100W | lc_tube_100,x_power W http://am.co.za/ | lc_tube_100,x_power_max W http://am.co.za/ | lc_tube_100,x_divergence mrad http://am.co.za/ | lc_tube_100,x_m2 http://am.co.za/ | lc_tube_100,x_diameter mm ±1mm |

| LC-TUBE/130 | TruCUT Standard 130W | lc_tube_130,x_power W http://am.co.za/ | lc_tube_130,x_power_max W http://am.co.za/ | lc_tube_130,x_divergence mrad http://am.co.za/ | lc_tube_130,x_m2 http://am.co.za/ | lc_tube_130,x_diameter mm ±1mm |

| LC-TUBE/150 | TruCUT Standard 150W | lc_tube_150,x_power W http://am.co.za/ | lc_tube_150,x_power_max W http://am.co.za/ | lc_tube_150,x_divergence mrad http://am.co.za/ | lc_tube_150,x_m2 http://am.co.za/ | lc_tube_150,x_diameter mm ±1mm |

30W/40W/60W CO2 Laser Tube http://am.co.za/

Our Low Power TruCUT CO2 Laser is suitable for fine surface engraving. Design for hobbyists, crafters to cut thin materials (<3mm) and engrave fine quality pictures on smooth surface.

80W/90W CO2 Laser Tube http://am.co.za/

Our TruCUT 90W CO2 Laser is suitable for laser marking, laser cutting and laser engraving which is the ideal choice of laser cut on thin plates include perspex, softwood etc, http://am.co.za/ laser cloth cutting and marble marking.

100W CO2 Laser Tube http://am.co.za/

Our TruCUT 100W CO2 Laser is suitable for leather carving and hollowing-out or embossing, http://am.co.za/ cloth cutting, lampshade making, signs, marks and artwork processing and truly boasts excellent engraving and cutting performances.

120W/130W CO2 Laser Tube http://am.co.za/

Our TruCUT 120W/130W CO2 Laser is suitable for the cutting of die-cutting plates, http://am.co.za/ thick acrylic plates and so on. It is widely used in the packaging industry which uses large quantities of medium density fiberboard and plywood cut by die-cutting machines. http://am.co.za/ In addition to the packaging industry, this Laser is also popular in the signage industry with the prominent usage of perspex, light guiding plates and display screens.

150W/160W/180W CO2 High-Power Laser Tube http://am.co.za/

Our TruCUT 150W - 180W CO2 Laser, which outputs between 150W and 180W of power, http://am.co.za/ is capable of cutting thin metal plates.

Cutting Table Size Options

| Desktop Laser http://am.co.za/ | Cabinet Laser http://am.co.za/ | Flatbed Laser #1http://am.co.za/ | |||||

|---|---|---|---|---|---|---|---|

| Base Model Number | 4030 | 6040 | 9060 | 1390 | 1325 | 2030 | 2040 |

| TruCUT CO2 Laser | lc_4030,pic | lc_6040,pic | lc_9060,pic | lc_1390,pic | lc_1325,pic | lc_2030,pic | lc_2040,pic |

| Width | 400mm | 600mm | 900mm | 1300mm | 1300mm | 2000mm | 2000mm |

| Length | 300mm | 400mm | 600mm | 900mm | 2500mm | 3000mm | 4000mm |

| Reflecting Mirrors | Default l_mirror_mo_30,pic Molybdenum Plated Laser Reflecting Mirror × 3 http://am.co.za/ Reflecting Rate ( Reflectivity ) ≈ 99% Each Optional l_mirror_si_30,pic Silicon Mirror Plated with Multi-layer Dielectric Film × 3 http://am.co.za/ Reflecting Rate ( Reflectivity ) ≈ 99.85% Each Optional l_mirror_k9_20,pic K9 Crystal Glass Gold-Plated Laser Reflecting Mirror × 3 http://am.co.za/ Reflecting Rate ( Reflectivity ) ≈ 99.5% Each ( for 60W Laser or less ) | ||||||

| Optical Focus Lens | Zinc-Selenide (ZnSe) Lens with Two Sides Anti-Reflection (AR/AR) Coating × 1 http://am.co.za/ Transmission Rate of AR/AR Coated CVD ( Chemical Vapor Deposition process ) http://am.co.za/ Zinc-Selenide Window ≈ 99% | ||||||

| Max Laser Travel Distance | 1200mm | 1500mm | 2000mm | 2700mm | 1800mm | 2500mm | 2500mm |

| Propagation Loss Use Silicon Mirrors | On Average, 3% http://am.co.za/ / Metre Energy Loss for Laser Beam Transmitted Through the Clean Air #2 | ||||||

| 3.6% http://am.co.za/ | 4.5% http://am.co.za/ | 6% http://am.co.za/ | 8.1% http://am.co.za/ | 5.4% http://am.co.za/ | 7.5% http://am.co.za/ | 7.5% http://am.co.za/ | |

| Laser Energy Efficiency | 92.601% | 91.737% | 90.296% | 88.279% | 90.872% | 88.855% | 88.855% |

#1 Laser Generating Device is mounted on Gantry on Flatbed model, therefor the length of cutting table won't effect the cutting efficiency. http://am.co.za/ General speaking, the laser cutting machines require to achieve laser efficiency higher than 90% with laser beam travel distance less than 3 metres.

#2 There is no absorption problem of laser light from either a Nd:YAG (1.06 microns) or CO2 (10.6 microns) laser in nitrogen, or in air without contaminants. http://am.co.za/ In real working environment, air has variable percentages of CO2 and water vapor and also tends to contain hydrocarbons, all of which absorb 10.6 um light. http://am.co.za/ If you do not have clean and dry working environment, the decrease of laser power is dramatically increase from 3% energy lose per meter to 20% or more per meter.

Laser Cutting Gas

A small air pump is included and functions as the default cutting air source for all our CO2 laser cutting tables. http://am.co.za/ Stronger pressure cutting air sources may be required if you are going to employ the melt and blown cutting method for non-metal materials, especially plastic materials. http://am.co.za/ This is to say, for melt and blown cutting on metal, except stronger air pressure requirements, as the cutting air compound may require to be replaced with oxygen or other metal cutting assistance gas for better cutting quality. http://am.co.za/ Otherwise, the molten dross tends to adhere to the underside of the cut surface. http://am.co.za/ For exceptionally clean cuts, very high gas pressures can be used.

Laser Lens & Lens' Focus Length ( FL )

The longer of the lens' Focus Length the longer the Depth Of Field ( DOF ) which increases the cutting thickness. http://am.co.za/ Increasing of FL, however, also results in bigger Spot Size on material, which means a wider cutting gap ( Kerf ) and lower energy density meaning that less material can be cut. http://am.co.za/ Customized lenses will provide any FL, commonly commercially available lenses are:

| Focus Length ( FL ) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 25.4 mm http://am.co.za/ | 38.1 mm http://am.co.za/ | 50.8 mm http://am.co.za/ | 63.5 mm http://am.co.za/ | 76.2 mm http://am.co.za/ | 101.6 mm http://am.co.za/ | 127.0 mm http://am.co.za/ | 190.5 mm http://am.co.za/ | ||

| Φ | 18 mm | -- | -- | -- | -- | -- | |||

| 19 mm | -- | -- | -- | -- | -- | ||||

| 20 mm | -- | -- | -- | -- | |||||

| 25 mm | -- | -- | -- | -- | -- | ||||

![]() indicates the Zinc-Selenide (ZnSe) Lenses we sell and the price associated with Lens diameter ( Φ ). http://am.co.za/ We may expand our product range later with additional sizes. http://am.co.za/ Focus length 50.8 mm for smaller table and 63.5mm for larger table are the most commonly used FL and is installed as the default focus lens for most our CNC Laser Cutters.

indicates the Zinc-Selenide (ZnSe) Lenses we sell and the price associated with Lens diameter ( Φ ). http://am.co.za/ We may expand our product range later with additional sizes. http://am.co.za/ Focus length 50.8 mm for smaller table and 63.5mm for larger table are the most commonly used FL and is installed as the default focus lens for most our CNC Laser Cutters.

Materials, Latent Heat Required for Fusion and Vaporization

:Laser Energy Absorption

- Unknown

- NOT ≤ 5%

- Poor ≤ 20%

- Fair ≈ 40%

- Good ≈ 60%

- Very Good ≥ 80%

- Excellent ≥ 90%

- Fusion

- Temperature required to melt the material, useful to laser welding as well as blow cutting. http://am.co.za/ Not all materials can melt.

- Vaporization

or.. Burning Temperature http://am.co.za/

Flame Temperature

Ignition Temperature

- Temperature required to vaporize the material, useful for laser cutting. http://am.co.za/ Everything can be vaporized when the temperature rises enough. http://am.co.za/

If the material will burn at vaporization temperature, a risk of fire is tremendous as well as a burning marks being visible on the cutting edge.

| Material | Specific Heat Capacity ( kJ/kg ) | Thermal Conductivity ( W/(m·K) ) | Density ( g/cm3 ) | Temperature ( ℃ ) For | Laser Energy Absorption | Commonly Known as | |||

|---|---|---|---|---|---|---|---|---|---|

| Fusion | Vaporization | CO2 | Nd:YAG | ||||||

| Plastic | ABS | 1.568 http://am.co.za/ | 0.8 http://am.co.za/ | 1.03 http://am.co.za/ | 120 | 416 | Excellent | Unknown | Acrylonitrile butadiene styrene |

| Plastic | PMMA | 1.467 http://am.co.za/ | 0.2 http://am.co.za/ | 1.18 http://am.co.za/ | 160 | 380 | Excellent | Unknown | Poly (methyl methacrylate), Acrylic Glass, Perspex, Plexiglas, Plexiglass |

| Wood | MDF | 1.7 http://am.co.za/ | 0.18 http://am.co.za/ | 0.75 http://am.co.za/ | -- | 220 | Very Good | Unknown | SupaWood, Medium Density Fiberboard |

| Metal | Stainless Steel | 0.5 http://am.co.za/ | 24 http://am.co.za/ | 8 http://am.co.za/ | 1510 | -- | 25% | Excellent | Inox Steel, Stainless Steel Alloy |

Disclaimer: the above data is gathered from various sources which may not be accurate, please contact us for correction. http://am.co.za/ If you would like to know about a laser cutting result on a material not listed here, please send the material name and physical characters to webmaster@am.co.za.

Laser Cutting Capacity Chart

Please note, laser device size increases as power increases, http://am.co.za/ so it's not easy to fit high-power laser onto small table.

| Laser Generating Device | Duty Cycle | On Table Size | Use Focus Lens | For Material | |

|---|---|---|---|---|---|

Use on Size Cutting Table

Wavelength is µm for laser. http://am.co.za/ Laser beam's widest diameter is mm, therefor all mirror sets and lenses should be chosen with required diameter larger than mm. http://am.co.za/ With laser duty cycle %, theoretically Watt ( with occasionally burst to Watt ) of laser energy will be delivered to the material on the cutting table.

With Lens's Focus Length: mm

Will deliver Depth Of Field ( DOF ) of mm and deliver energy to each mm2 is W and bursts to W occasionally.

Will W/mm2 Laser Power Cut on room temperature 25℃

We do not have data on how absorbs laser energy, there for the engraving or cutting result cannot be estimated.

Disclaimer

The above data and calculation is theoretical and may not truly reflect the capability our laser machines provide. http://am.co.za/ We will not take responsibility for your purchase decision purely based on this data. http://am.co.za/ You are always more than welcome to do a test cut on your material with our demo machines.

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 2013/08/24 13:51 . [ Homepage | Price List | Visit Us ]