CNC Hypertherm Powermax Plasma Buying Guide

Hypertherm products are reliable, consistent and easily outperform anything else in their class. http://am.co.za/ Hypertherm Powermax systems are tested under strict protocols which ensure the highest levels of performance and reliability. http://am.co.za/ You can be confident that Hypertherm Powermax systems will perform reliably under the toughest conditions.

Why choose Hypertherm Powermax over Oxy-Fuel?

Cutting with a Hypertherm Powermax system does not require flammable gases for pre-heating; http://am.co.za/ provides faster cutting speeds on metals up to 32 mm thick while simultaneously delivering better cut quality and fewer secondary operations. http://am.co.za/ Hypertherm Powermax systems are easily used with templates, will cut stacked, painted or rusted metal, and any electrically conductive metal type such as stainless steel and aluminium.

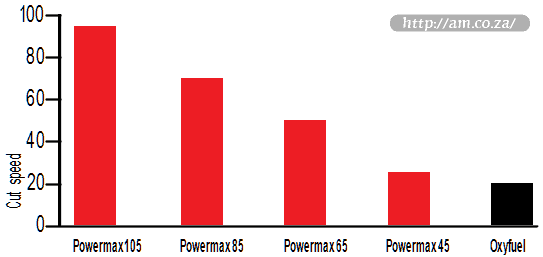

Cut Speed Comparison with Oxyfuel on 12 mm Mild Steel

![]()

With the best-selling system of Hypertherm, the Powermax45 is the most versatile and portable 12mm machine on the market, with a broad set of application capabilities that make it a truly multi-purpose tool. http://am.co.za/ The Powermax45 cuts or gouges faster, easier and better than any other product in its class.

![]()

With the most torch options in the industry and the latest technological innovations, the Powermax65, Powermax85 and the new Powermax105 help you do more than ever before. http://am.co.za/ Seven Duramax torch styles provide greater versatility for hand, portable automation, X-Y table and robotic cutting and gouging. Smart Sense technology automatically adjusts gas pressure according to cutting mode and torch lead length for optimum cutting. http://am.co.za/ In the Powermax105, it also detects consumable end-of-life, automatically turning off power to the torch to prevent potential damage to other parts or the work piece.

Hypertherm Powermax Capacity

Cutting thickness in mm and cutting speed in mm/min. http://am.co.za/ Pierce rating for CNC machine with automatic torch height control. All our Hypertherm Powermax CNC Plasma Cutters boast torch height control devices.

|  |  |  | |

| Powermax System | Powermax45 | Powermax65 | Powermax85 | Powermax105 |

|---|---|---|---|---|

| Recommended | 12 mm / 500 | 20 mm / 500 | 25 mm / 500 | 32 mm / 500 |

| 20 mm / 250 http://am.co.za/ | 25 mm / 250 http://am.co.za/ | 32 mm / 250 http://am.co.za/ | 38 mm / 250 http://am.co.za/ | |

| Severance | 25 mm / 125 min | 32 mm / 125 | 38 mm / 125 | 50 mm / 125 |

| Pierce Capacity | 12 mm http://am.co.za/ | 16 mm http://am.co.za/ | 20 mm http://am.co.za/ | 22 mm http://am.co.za/ |

Gouge Capacity

|  |  |  | |

| Powermax System | Powermax45 | Powermax65 | Powermax85 | Powermax105 |

|---|---|---|---|---|

| Metal Removed per Hour | 2.8 kg | 4.8 kg | 8.8 kg | 9.8 kg |

| Depth × Width2 | 3.3 mm × 5.5 mm | 3.5 mm × 6.6 mm | 5.8 mm × 7.1 mm | 6.4 mm × 7.4 mm |

System Specifications

|  |  |  | |

| Powermax System | Powermax45 | Powermax65 | Powermax85 | Powermax105 |

|---|---|---|---|---|

| Input Current | 10.5 A @ 5.95 kW http://am.co.za/ | 15.5 A @ 9 kW http://am.co.za/ | 20.5 A @ 12.1 kW http://am.co.za/ | 30 A @ 16.8 kW http://am.co.za/ |

| Output Current | 20 - 45 A http://am.co.za/ | 20 - 65 A http://am.co.za/ | 25 - 85 A http://am.co.za/ | 30 - 105 A http://am.co.za/ |

| Rated Output Voltage | 132 VDC | 139 VDC | 143 VDC | 160 VDC |

| Duty Cycle at Full Output # | 50% @ 45 A 60% @ 41 A 100% @ 32 A | 50% @ 65 A 100% @ 46 A | 60% @ 85 A 100% @ 66 A | 80% @ 105 A 100% @ 94 A |

| Dimensions With Handle Depth × Width × Height | 426 × 172 × 348 mm | 500 × 234 × 455 mm | 500 × 234 × 455 mm | 592 × 274 × 508 mm |

| Weight with Torch | 16 kg | 26 kg | 28 kg | 45 kg |

Hypertherm's duty cycle ratings are established at 40°C (according to international standards) http://am.co.za/ and are determined at actual cutting arc voltage levels. http://am.co.za/ Competitive systems are often rated at room temperature (approximately 20°C) http://am.co.za/ and at theoretical output voltages, which allows for duty cycle ratings to be significantly overstated.

Recommended Gas Inlet Flow Rate/Pressure

Compressed air – shop air, portable air compressor or bottled air. http://am.co.za/ Nitrogen may also be used.

| Powermax System | Powermax45 | Powermax65 | Powermax85 | Powermax105 |

|---|---|---|---|---|

| Gas Supply | Compressed Air or N2 (Nitrogen) | |||

| Cutting | 170 l/min @ 5.5 Bar http://am.co.za/ | 189 l/min @ 5.6 Bar http://am.co.za/ | 189 l/min @ 5.6 Bar http://am.co.za/ | 217 l/min @ 5.9 Bar http://am.co.za/ |

| Gouging | 170 l/min @ 4.1 Bar | 212 l/min @ 4.8 Bar | 212 l/min @ 4.8 Bar | 227 l/min @ 4.8 Bar |

Is Hypertherm Powermax suitable for your business?

Please Read CNC Plasma Cutter Buying Guide

| Entry | Standard | Large | Ultimate |

|---|---|---|---|

|  |  |  |

| Our most affordable option, everyone can afford one portable CNC plasma cutter | Choose Hypertherm Powermax, choose our standard CNC plasma cutter | Want more from Hypertherm Powermax, choose our large-size CNC plasma cutter | With the power of Hypertherm HRP Series, our High-Definition CNC Plasma cutter is the best of best |

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 19:35 2013/04/02 . [ Homepage | Price List | Visit Us ]