Hypertherm HyPerformance

CNC Plasma Cutter

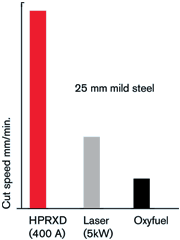

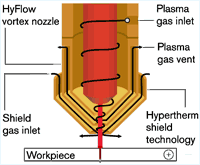

As the world's leading plasma cutting system, Hypertherm HyPerformance HPRXD Family plasma cutting system provides cutting of the highest quality, even on more thick and bulky material. http://am.co.za/ By incorporating Hypertherm's proven HyDefinition, LongLife, http://am.co.za/ and patented PowerPierce and True Hole technologies, Hypertherm HyPerformance Plasma boosts overall performance, productivity and profitability of your organization. http://am.co.za/ The system offers process flexibility that is unparalleled and enables you to cut, bevel and mark metals of up to 160 mm thick.

The Power of Hypertherm HPRXD

Hypertherm HyPerformance Plasma cuts fine-feature parts with great quality and consistency http://am.co.za/ and in doings so it virtually eliminates the cost of any secondary operations.

HyDefinition and LongLife

These systems deliver more consistent cut quality http://am.co.za/ over a long period than other systems available on the market.

These systems deliver more consistent cut quality http://am.co.za/ over a long period than other systems available on the market.

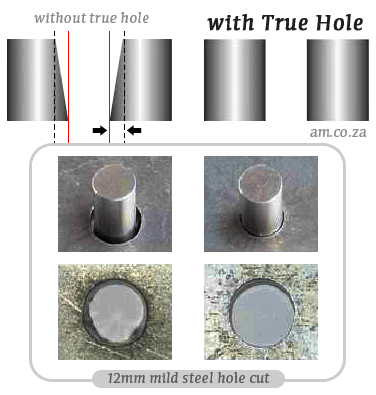

True Hole Technology

HyPerformance Plasma auto gas systems produce hole quality on mild steel http://am.co.za/ that is significantly better than what was previously achievable using plasma technology.

PowerPierce & HDi for Stainless Steel Cutting

Hypertherm is the leading stainless steel cutting machine, http://am.co.za/ with new HDi technology for thin stainless steel, optimized gas mixing for mid-range thicknesses and patented PowerPierce technology combined with an innovative controlled pierce process for the thickest piercing and cutting capability available.

|  |  |  |  | |

| HPR Plasma | HPR130XD http://am.co.za/ | HPR260XD http://am.co.za/ | HPR400XD http://am.co.za/ | HPR800XD http://am.co.za/ | |

|---|---|---|---|---|---|

| Input Current | 34 A http://am.co.za/ | 84 A http://am.co.za/ | 138 A http://am.co.za/ | 138 A Per Power Supply http://am.co.za/ 276 A in Total | |

| Output Current | 30 - 130 A http://am.co.za/ | 30 - 260 A http://am.co.za/ | 30 - 400 A http://am.co.za/ | 30 - 800 A http://am.co.za/ | |

| Output Voltage | 50–150 VDC | 175 VDC | 200 VDC | 200 VDC Per Power Supply | |

| Plasma Gas Supply | Oxygen (O2), Nitrogen (N2), http://am.co.za/ F5 Gas (5% H, 95% N), H35 Gas (35% H, 65% Ar), Compressed Air http://am.co.za/ or Argon (Ar) | ||||

| Shield Gas Supply | Nitrogen (N2), Oxygen (O2), http://am.co.za/ Compressed Air or Argon (Ar) | ||||

| Gas Pressure | 8 Bar http://am.co.za/ | ||||

| Virtually Dross-free Cutting Capacity | 16 mm http://am.co.za/ | 32 mm http://am.co.za/ | 38 mm http://am.co.za/ | 38 mm http://am.co.za/ | |

| Pierce Capacity | 32 mm http://am.co.za/ | 38 mm http://am.co.za/ | 50 mm http://am.co.za/ | 50 mm http://am.co.za/ | |

| Severance | 38 mm http://am.co.za/ | 64 mm http://am.co.za/ | 80 mm http://am.co.za/ | 80 mm http://am.co.za/ | |

| Production Pierce | 20 mm http://am.co.za/ | 32 mm http://am.co.za/ | 45 mm http://am.co.za/ | 75 mm http://am.co.za/ | |

| Severance | 25 mm http://am.co.za/ | 50 mm http://am.co.za/ | 80 mm http://am.co.za/ | 160 mm http://am.co.za/ | |

| Production Pierce | 20 mm http://am.co.za/ | 25 mm http://am.co.za/ | 38 mm http://am.co.za/ | 75 mm http://am.co.za/ | |

| Severance | 25 mm http://am.co.za/ | 50 mm http://am.co.za/ | 80 mm http://am.co.za/ | 160 mm http://am.co.za/ | |

| More Specs @ Hypertherm.com | HyPerformance HPR130XD | HyPerformance HPR260XD | HyPerformance HPR400XD | HyPerformance HPR800XD | |

The CNC Cutting System

The CNC Cutting System

- Torch Lift Distance

- ≤160 mm http://am.co.za/

- Cutting Speed

- 20 - 10 000 mm/min http://am.co.za/

- Demo Speed

- 0 - 10 000 mm/min (Simulate Cutting)

- Driving System

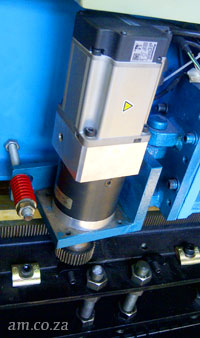

- 3 Panasonic MINAS A4 Series AC Servo Motors

Whole movement driven by three world best servo motors by Panasonic. http://am.co.za/ There are two servo motors on each side of the gantry beam for Y-Axis movement and one servo motor on the body drive torch on Y-Axis. Each servo motor is controlled by one dedicated servo motor controller.

Whole movement driven by three world best servo motors by Panasonic. http://am.co.za/ There are two servo motors on each side of the gantry beam for Y-Axis movement and one servo motor on the body drive torch on Y-Axis. Each servo motor is controlled by one dedicated servo motor controller.High-functionality Real-Time Auto-Gain Tuning

- Corresponds to even variation of load inertia. Offers real automatic gain tuning to low and high stiffness machines with a combination of an adaptive filter;

- Supports the vertical axis application where the load torque is different in rotational direction;

- Prevents the machine from over-traveling during automatic gain tuning with its over-travel detecting function.

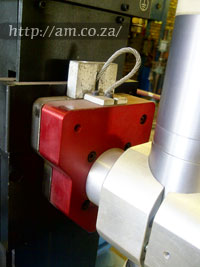

- Transmission System

- Gearbox, Gear & Rack

- Cooling System

20A Dedicated Chilling System Continuously monitors coolant temperature and flow-rate to ensure optimal performance

- Gas Control System

Auto Gas Console

- Simplifies operator training requirements by allowing full control of all the plasma system settings from the CNC;

- To enable rapid switching http://am.co.za/ between cutting and marking, the Auto Gas Console automatically changes processes;

- To produce the most consistent cutting performance, http://am.co.za/ the Auto Gas Console automatically adjusts for variations in incoming gas;

- The Auto Gas Console is required to enable True Hole technology and optimized gas mixing for mid-range stainless cutting.

The CNC Plasma Cutter Control System:

Hypertherm EDGE Pro Shape Cutting Control

The EDGE Pro CNC builds on more than 40 years of Hypertherm's experience in the cutting industry. http://am.co.za/ Designed to be flexible and easy to use, the EDGE Pro delivers reliable performance for improved profitability. Using Phoenix software, this CNC improves cut quality and productivity by delivering our expertise directly to your factory and, by so doing, http://am.co.za/ ensuring that you have your best operator on every shift.

Hypertherm EDGE Pro Plasma CNC Control Standard Features

- Operating System

Windows XP Embedded, a Componentized Version of Microsoft Windows XP Professional

Windows XP Embedded, a Componentized Version of Microsoft Windows XP Professional- Hard Drive

- SATA Drive HDD

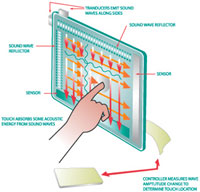

- Display Monitor

- 15" Antiglare Glass Touchscreen

(Surface Acoustic Wave Technology)- Pure-glass touchscreens for crystal clear image clarity, http://am.co.za/ resolution, and light transmission;

- Durable, http://am.co.za/ scratch-resistant and vandal-proof glass surfaces;

- Stable, "drift-free" operation for touch response that's always accurate;

- Superior touchscreen response is superfast due to the efficient algorithms and electronics as well as super Sensitive because it recognizes touch location and pressure;

- Finger, gloved hand, and soft stylus activation.

- Memory

- ≥ 1GB

- Interfaces

Two USB 2.0 Ports

Two USB 2.0 Ports- One HYPERNET Port

- One LAN Networking Port

- Two COM Serial Ports

- Regulatory Compliance

- CE, CSA

- Software Utilities

Part Program Support (PPS), Remote Help, Networking, Autogas Support, DXF Import, and Simple Shape Nesting

Part Program Support (PPS), Remote Help, Networking, Autogas Support, DXF Import, and Simple Shape Nesting

EDGE Pro Enhance Plasma Cutting Performance

After years' experience in cutting, Hypertherm engineers have learned the critical parameters to achieve superior quality performance on every part.

- Critical plasma, http://am.co.za/ THC and table parameters can be controlled in the part program using Part Program Support (PPS) for the same cut quality every time;

- Cutting applications include high definition, http://am.co.za/ conventional, single-bevel or dual-bevel plasma capability;

- Watch Windows enable on-screen real-time monitoring of key process performance parameters while cutting;

- Custom cut charts can be created and controlled in the part program or made available to the CutPro Wizard;

- Support for fast transitions from marking to cutting.

The Torch Height Control System

Hypertherm ArcGlide THC

ArcGlide THC has been designed to deliver optimized performance with minimal operator input. http://am.co.za/ The ArcGlide THC provides superior performance and reliability for plasma applications while reducing the cost of cutting.

Optimize Cut Quality and Consumable Life

While traditional torch height controls require operators to periodically adjust arc voltage to ensure proper cut height, http://am.co.za/ the ArcGlide THC continuously samples arc voltage and automatically adjusts arc voltage for proper torch height over the life of the consumables without requiring operator input by using Hypertherm's proprietary techniques.

- Performance advantages are achievable with minimal operator input, http://am.co.za/ eliminating the need for extensive training and allowing you the best performance across any shift with any operator at any plant;

- Automated Initial Height Sense (IHS) crossover height calibration to minimize the time for the torch to find the plate without risking torch damage;

- Durable magnetic breakaway for all-round protection of the torch during collisions with rapid re-install.

| Improper cut height due to not adjusting arc voltage for electrode wear | Proper cut height automatically maintained by ArcGlide THC |

Partially worn electrode http://am.co.za/ Plate contact can damage consumables |  Partially worn electrode Proper cut height http://am.co.za/ |

| Consumables Discarded Prematurely | Consumable Life and Cut Quality Optimized |

Hypertherm ArcGlide THC Standard Features

- Stroke Speed

- 15 240 mm/min http://am.co.za/

- Lifter Stroke Length

- 241 mm http://am.co.za/

- Regulatory

- CE, CSA, GOST-R

- Communication Protocol

- Discrete Wiring

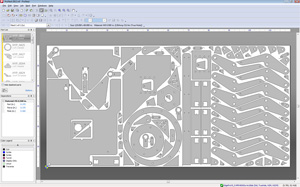

Nesting Software: Hypertherm ProNest 2012

ProNest nesting software gives mechanized cutting users an efficient and intuitive solution for advanced multi-process profiling operations. http://am.co.za/ ProNest seamlessly integrates with your business and is fully configurable to meet your needs. ProNest is also backed by the high quality technical support that you deserve.

Hypertherm ProNest Standard Features Highlights

Part Creation and Development

Part Creation and Development

- Integrated 2D CAD program to create and edit CAD files http://am.co.za/;

- Variable Shape Parts feature to develop common parts from templates.

CAD/CAM Import and Conversion

- Import CAD and CNC files (many industry-standard file formats);

- Import Bill of Materials properties from CAD files http://am.co.za/;

- Automatic CAD file correction and error notification;

- Automatic spline / ellipse smoothing and reduction http://am.co.za/;

- Separate multiple parts from a single CAD file;

- Automatic mapping of CAD layers to processes (cut, mark, etc.).

Interactive Manual Nesting

- Group parts into clusters for nesting;

- Drag, drop and bump parts on the nest;

- Duplicate, move, scale, http://am.co.za/ mirror, rotate, or array parts;

- Prohibit / permit nesting inside of a part;

- Multi-sheet and multi-head nesting;

- Part interference detection;

- Edit lead-in/lead-out position http://am.co.za/ and properties within the nest;

- Automatically update nest with part revisions;

- Grain constraint, automatic tabbing / micro-joints, edge pierce technology;

- Material database (with grade and gauge), http://am.co.za/ plate list and part library;

- Manual and automatic plate cropping;

- Safe zones for plate clamping applications;

- Automatic and manual nest sequencing; http://am.co.za/

- Control cut direction and cut sequencing on part-by-part basis;

- Animated cutting sequence simulation.

Built-in Process Parameters

- Material type, thickness, http://am.co.za/ grade and class-based process parameters;

- Material type and thickness based lead-in/out parameters;

- Automatic and interactive separations for part, plate, and pierce spacing.

Reporting

- Customizable management and shop reports;

- Export reports directly to PDF, http://am.co.za/ Excel spreadsheet (*.xls), or (*.csv).

Costing

- Detailed user-defined machine and labour production costing;

- Automatic calculation of part production costs and part/nest utilization.

Output

Output

- Flexible post-processor with standard NC output;

- Automatic kerf / pre-kerf compensation;

- DXF output.

Hypertherm HPRXD CNC Plasma Pricing

Similar to our large size gantry plasma cutting machine, Hypertherm HPRXD CNC Plasma does not include the cutting table in the price listed on our website. http://am.co.za/ This is due to the fact that the cutting table is a pure steel structure and will be manufactured locally by our previous clients. http://am.co.za/ Or you can build the cutting table yourself, since most of our Hypertherm HPRXD clients have the metal fabrication ability in them factory already.

Build To Order: Customization and Manufacture

Our Hypertherm HPR CNC Plasma cutter is Build-To-Order (BTO), http://am.co.za/ which means once we have your order, we will start to build the machine in our factory in China, then transport it to your premises. http://am.co.za/ This also gives you the ability to customize your machine, although many components can be changed but the above configuration is our recommended approach since it has been proven as the best setup for the best results and will thus be worth your every cent.

Lead Time and Payment Terms

After your initial payment, which is 1/3 of full amount, our factory will build your machine. http://am.co.za/ Sea freight from China to South Africa roughly takes about two months. After your machine arrived at our warehouse, you will have to pay final payment before delivering and assembling the machine on your premises and handover.

| Working Area | ||||

|---|---|---|---|---|

| Hypertherm | 2500 × 6000 P-2560 http://am.co.za/ | 2500 × 8500 P-2585 http://am.co.za/ | 2500 × 11000 P-25110 http://am.co.za/ | |

| HPR130XD | H130 | p_2560_h130,price http://am.co.za/ | p_2585_h130,price http://am.co.za/ | p_25110_h130,price http://am.co.za/ |

| HPR260XD | H260 | p_2560_h260,price http://am.co.za/ | p_2585_h260,price http://am.co.za/ | p_25110_h260,price http://am.co.za/ |

| HPR400XD | H400 | p_2560_h400,price http://am.co.za/ | p_2585_h400,price http://am.co.za/ | p_25110_h400,price http://am.co.za/ |

| HPR800XD | H800 | p_2560_h800,price http://am.co.za/ | p_2585_h800,price http://am.co.za/ | p_25110_h800,price http://am.co.za/ |

| Liner Guide Rails Length | 7 500 mm | 10 000 mm | 12 500 mm | |

Please note that the above prices exclude VAT, http://am.co.za/ exclude logistics costs from our warehouse to your promises. On-site installation is also included. Furthermore, http://am.co.za/ CNC training courses are provided to insure you always have operators for this masterpiece of machinery.

Don't forget we have a lowest-price guarantee, http://am.co.za/ so if you have found any local competitor offering a similar setup at a lower cost, please let us know and we will beat it.

Is this ultimate CNC Plasma Cutter suitable for your business?

Please Read CNC Plasma Cutter Buying Guide

| Entry | Standard | Large | Ultimate |

|---|---|---|---|

|  |  |  |

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 14:13 2013/04/29 . [ Homepage | Price List | Visit Us ]