CNC Plasma Cutting Machine for Sale

Our CNC Plasma Cutter buying guide is the best point to begin when you start to look for your next or first CNC Plasma Cutting machine. http://am.co.za/ Our CNC Plasma Cutters are quality build and super affordable for all your profile cutting needs.

CNC Plasma Cutters for Sale in South Africa - We offer best CNC plasma cutters, plasma cutter spare parts, technical support and buying guide.

This page no longer updating. Older models sold out.

Please visit www.CNCPlasmaTable.co.za for more up-to-date information.

If you are searching for an unparalleled CNC plasma-cutting machine, look no further than am.co.za. Renowned for their exceptional industrial machinery and consumables range, am.co.za presents many state-of-the-art CNC machines designed to revolutionize your metal fabrication processes. Precision is elevated to new heights with its plasma cutting machine for sale as it effortlessly slices through various types of metals with meticulous accuracy.

The advanced technology incorporated within this innovative tool ensures flawless cuts that meet the highest industry standards. From intricate patterns to complex shapes, the CNC plasma cutting machine offered by us delivers flawlessly executed designs, empowering users to achieve remarkable results consistently. Whether you operate a small business or handle large-scale production requirements, this powerful machine caters perfectly to all your needs while delivering uncompromised performance and efficiency day after day.

CNC Plasma Cutter Buying Guide

When exploring the plethora of CNC plasma cutters available on the market, it is imperative to consult a reliable source for guidance. The CNC Plasma Cutter Buying Guide by us is invaluable for those seeking a professional and comprehensive understanding of these cutting-edge machines. Bursting with meticulous insights and expert recommendations, this guide outlines critical considerations such as power output, cutting capacity, precision control systems, and durability.

By leveraging their industry expertise and vast knowledge base, am.co.za provides potential buyers with detailed explanations of various features significantly impacting performance outcomes. Additionally, they emphasize the significance of evaluating machine compatibility with different software programs to ensure seamless integration into existing workflows. As one dives into each chapter of this buying guide by us, they are greeted with eloquent descriptions and simplified explanations in a tone that resonates with professionalism throughout every paragraph.

What is the best CNC Plasma Cutting Machine for your business?

Knowing your requirements is an essential facet when trying to find the best CNC Plasma Cutter that is perfectly suitable for your business. http://am.co.za/ The requirements that you need to bear in mind include:

- The material you need to cut http://am.co.za/

- The thickness of the material

- The largest size of your raw material sheet http://am.co.za/

- The quality required of the cutting

- The next step for the cutouts

Advanced Machinery offers four main types of CNC Plasma Cutters for sale:

- Entry Level

CNC Plasma Cutter - Suitable for making metal-arts, signage frames, trailers, gates etc. http://am.co.za/ that mainly require cutting mild steel, up to 10mm with low precision and low productively;

- Standard

CNC Plasma Cutter - Suitable for small workshops and/or engineering companies for all kinds of general purpose cutting;

- Large Size

CNC Plasma Cutter - The much larger working area and thicker cutting ability than standard means that the Large Size CNC Plasma Cutter is suitable for middle size engineering companies;

- Ultimate

CNC Plasma Cutter - This market leading cutter provides you with high-definition cutting quality, http://am.co.za/ from the thickest materials in the fastest time.

Since our CNC Plasma Cutter is quality build and super affordable, our clients often say "that's not bad" after hearing about our prices. http://am.co.za/ So if you have funding and require the quality and speed that the Ultimate CNC cutter has to offer, please go to our Ultimate CNC Plasma. It's simply the most advanced CNC cutter on the market.

Plasma Cutting Thickness & Materials

When you choose the thickness, use Pierce thickness value for your decision making. If you demand a better cutting quality on mild steel, use the Virtually Dross-free cutting thickness value. http://am.co.za/ It's always preferred to start from the edge, but when you cannot start from the edge of the plate, for example: cutting a hole, you have to pierce through the metal plate first. http://am.co.za/ If you cannot pierce through a metal place, you cannot cut.

| Mild Steel (Carbon Steel) | Stainless Steel | Aluminium | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Plasma System | Virtually Dross-free http://am.co.za/ | Pierce http://am.co.za/ | Severance http://am.co.za/ | Pierce | Severance | Pierce | Severance | ||

| Entry | DRUMBO CUT-100 | 3 mm http://am.co.za/ | 10 mm http://am.co.za/ | 18 mm | 8 mm http://am.co.za/ | 15 mm | 8 mm http://am.co.za/ | 15 mm | |

| Standard | Powermax45 | 4 mm | 12 mm http://am.co.za/ | 25 mm | 10 mm http://am.co.za/ | 20 mm | 10 mm http://am.co.za/ | 20 mm | |

| Powermax65 | 6 mm | 16 mm http://am.co.za/ | 32 mm | 12 mm http://am.co.za/ | 25 mm | 12 mm http://am.co.za/ | 25 mm | ||

| Powermax85 | 8 mm | 20 mm http://am.co.za/ | 38 mm | 16 mm http://am.co.za/ | 30 mm | 16 mm http://am.co.za/ | 30 mm | ||

| Powermax105 | 10 mm | 22 mm http://am.co.za/ | 50 mm | 17 mm http://am.co.za/ | 40 mm | 17 mm http://am.co.za/ | 40 mm | ||

| Large | |||||||||

| MAXPRO200 | 20 mm | 32 mm http://am.co.za/ | 75 mm | 25 mm http://am.co.za/ | 60 mm | 25 mm http://am.co.za/ | 60 mm | ||

| Ultimate | HPR130XD | 16 mm | 32 mm http://am.co.za/ | 38 mm | 20 mm http://am.co.za/ | 25 mm | 20 mm http://am.co.za/ | 25 mm | |

| HPR260XD | 32 mm | 38 mm http://am.co.za/ | 64 mm | 32 mm http://am.co.za/ | 50 mm | 25 mm http://am.co.za/ | 50 mm | ||

| HPR400XD | 38 mm http://am.co.za/ | 50 mm | 80 mm | 45 mm http://am.co.za/ | 80 mm | 38 mm http://am.co.za/ | 80 mm | ||

| HPR800XD | 38 mm | 50 mm | 80 mm | 75 mm http://am.co.za/ | 160 mm | 75 mm http://am.co.za/ | 160 mm | ||

| |||||||||

It will be faster for a more powerful system cutting on the same thickness.

CNC Plasma Cutter Components Recommendation

| Entry Level CNC Plasma Cutter | Standard CNC Plasma Cutter | Large CNC Plasma Cutter | Ultimate CNC Plasma Cutter | ||

|---|---|---|---|---|---|

| X-Axis Driving | Stepper Motor | Panasonic Servo Motor http://am.co.za/ (Choose Servo Motor for more reliable performance) | |||

| Y-Axis Driving | Single Stepper Motor | Twin Stepper Motor | Twin Panasonic Servo Motor | ||

| Torch Height Control | Mechanical THC | Hypertherm ArcGlide THC | |||

| Arc Voltage THC http://am.co.za/ (Choose THC controlled by Arc sensor, only choose Mechanical THC if you are cutting ≤3mm metal sheet most of time) | |||||

| CNC Control System | FangLing F2100B CNC Machine Control System (PDF) | Hypertherm EDGE Pro | |||

| Nesting Software | FastCAM Software | Hypertherm ProNest Software | |||

| Cutting Area Size | Up to 1500 × 3000 mm http://am.co.za/ | Up to 2000 × 3000 mm http://am.co.za/ | Recommend and from 2500 × 6000 mm | ||

| Up to 2500 × 11000 mm | Up to any size, fully customizable | ||||

| Working Area | Providing 1 meter of space on each side of the cutting area is enough to operate the CNC plasma cutting machine. http://am.co.za/ More space is preferable for loading metal plate, especially when you load by forklift. | ||||

| Cutting Table | Flat Cutting Table, No Collector | Normal Table with collect drawer or Water Table | Price does not include cutting table, http://am.co.za/ recommend water table which will be manufacture locally | ||

| Water table is much better for plasma cutting over Downdraft Cutting Table. | |||||

Plasma Cutting Quality

Plasma cutting technology has been existing and continually improving for more than 30 years. http://am.co.za/ The quality of plasma cutting is far better than flame oxy-fuel cutting. And most importantly, only a little bit of treatment is needed for the cutout work piece to be weldable, not like a work piece cut out by oxy-fuel. http://am.co.za/ Despite the long waiting preheating time of oxy-fuel cutting, the secondary operation is also time consuming and costly. Why choose Plasma over Oxy-Fuel?

Our CNC plasma cutting machines provide the precision control on speed and arc-voltage to give the best possible cutting quality the plasma power source can provide. http://am.co.za/ With the tremendous advantage it offers over a hand-held plasma cutter, only two variables need your attention: the gradient and the dross.

Our CNC plasma cutting machines provide the precision control on speed and arc-voltage to give the best possible cutting quality the plasma power source can provide. http://am.co.za/ With the tremendous advantage it offers over a hand-held plasma cutter, only two variables need your attention: the gradient and the dross.

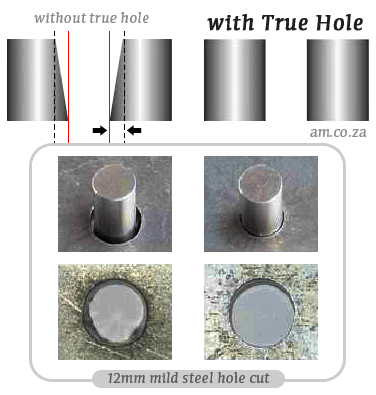

The Gradient

Unless you are choosing the ultimate CNC Plasma Cutter which has Hypertherm True-Hole technology, you will have a gradient on the work piece. http://am.co.za/ The gradient and kerf can be measured and compensated for in our CNC plasma control system and removed in secondary operations, for example: grinding.

The Dross

No plasma system will provide you with a dross-free cut, only virtually dross-free cut. http://am.co.za/ From the virtually dross-free thickness, more and more dross will be stuck on the work piece while the metal plate becomes thicker and thicker. Dross can be easily removed in secondary operation, for example: grinding as well.

Physical Limitations

All our CNC Plasma Cutters make use of both 220V home electricity (for CNC table, control and motors etc.) and 380V industry electricity (for plasma cutting system, also call plasma power source, plasma generator). http://am.co.za/ If you do not have 380V three-phase industry power on your premises, your best chance is to utilize a phase converter.

The required electric current and gas supply for plasma cutting system as following:

| Plasma System | Required Input Current | Required Plasma Gas | Required Shield Gas | Gas Pressure | ||

|---|---|---|---|---|---|---|

| Entry | DRUMBO CUT-100 | 26 A | Compressed Air http://am.co.za/ | No Need | 6 - 8 Bar | |

| Standard | Powermax45 | 10.5 A http://am.co.za/ | 5.5 Bar | |||

| Powermax65 | 15.5 A http://am.co.za/ | 5.6 Bar | ||||

| Powermax85 | 20.5 A | |||||

| Powermax105 | 30 A http://am.co.za/ | 5.9 Bar | ||||

| Large | ||||||

| MAXPRO200 | 57 A | Compressed Air, http://am.co.za/ Oxygen (O2), Nitrogen (N2) | Compressed Air, Nitrogen (N2) | 6.2 ± 0.7 Bar | ||

| Ultimate | HPR130XD | 34 A http://am.co.za/ | Compressed Air, http://am.co.za/ Oxygen (O2), Nitrogen (N2), F5 Gas (5% H, 95% N), H35 Gas (35% H, 65% Ar) or Argon (Ar) | Compressed Air, Nitrogen (N2), Oxygen (O2) or Argon (Ar) | 8 Bar | |

| HPR260XD | 84 A http://am.co.za/ | |||||

| HPR400XD | 138 A http://am.co.za/ | |||||

| HPR800XD | 276 A http://am.co.za/ |

CNC Plasma Cutter Prices

| SKU | CNC Plasma Cutters | Price | list,Plasma |

|---|

Need More Help

Don't hesitate to contact us for any sales or technical questions about our CNC Plasma Cutters. http://am.co.za/ We may choose to visit your workshop to become familiar with your specified requirements. We will also ask you to visit our showroom or visit our previous clients for demonstrations.

AM.CO.ZA is not affiliated with Hypertherm, Inc. Reference to machines, parts, descriptions, and model numbers are for convenience in verifying compatibility only. HYPERTHERM is a registered trademark of Hypertherm, Inc.

Our Happy Clients

Click on each company logo to learn them story:

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 2013/06/18 11:59 . [ Homepage | Price List | Visit Us ]

Download Printable PDF

Download Printable PDF