Laser Cutting in TruCUT Laser Software

Fast and quality laser cutting is controlled by our TruCUT Laser Cutter software. http://am.co.za/ Adjust the laser energy and speed on the lines and corners for smooth cutting of various kinds of material. http://am.co.za/ The cutting path optimization feature enables the identification of a general cutting path automatically, http://am.co.za/ plus the compensation settings prevent backlash and inertia

for smart and easy laser cutting.

Since 2019, we have been using the TruCUT RDWorks system. Please check out the RDWorks Training VideosRDWorks Training Videos here. The following information is for software prior to 2019.

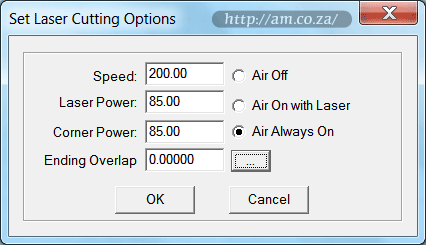

How-to Perform Laser Cutting

Double click the layer identification colour in the Layer Management http://am.co.za/ interface, and then a dialog box pops up as below:

- Speed

- Operating speed of the laser nozzle in cutting. http://am.co.za/

- Laser Power

- Adjust the minimum unit percentage of the laser power in operating the layer. http://am.co.za/

- Corner Power

- Adjust the power of the laser beam when its speed is at a minimum in the variable speed motion. http://am.co.za/ Adjustment of the corner laser power parameter can ensure an unchanged strength of the laser beam as it in smooth line.

- Ending Overlap

- Closed object may not be able to fully cut out due to mechanical inaccuracy. http://am.co.za/ This parameter helps to solve the problem, but it should not be set too large. http://am.co.za/ It is recommended that you adjust the mechanical precision to solve the problem.

- Air Off

- Not to blow air in the process.

- Air On with Laser

- Blow when the laser in on, stop blowing when the laser is off. http://am.co.za/

- Air Always On

- Start to blow at the moment the laser begins to move until the end of the cutting process. http://am.co.za/

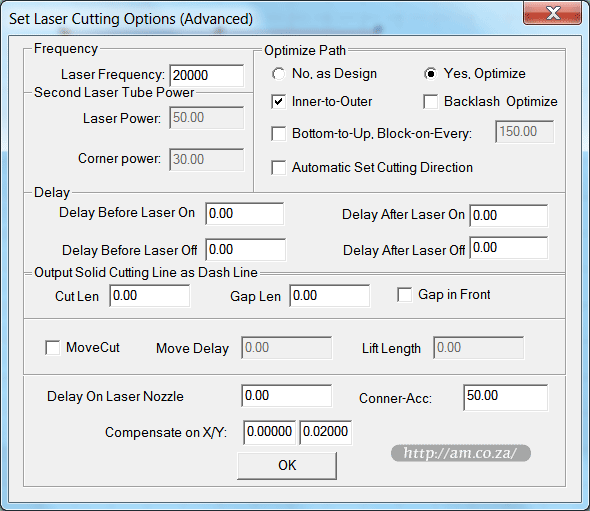

Advanced Laser Cutting Settings

To set advanced parameters -- click the "..." http://am.co.za/ button, a dialog box appears as below:

- Laser Frequency

- Control of the frequency of the laser's PWM signal in the process, http://am.co.za/ only useful for controlling the radio-frequency tube.

- Second Laser Power

- Adjust the minimum unit percentage of the second laser power in operating the layer. http://am.co.za/ This option will only be available for twin-laser machines.

- Second Laser Corner Power

- Adjust the power of the second laser when its speed is at a minimum in the variable speed motion. http://am.co.za/ This option will only be available for twin-laser machines.

Cutting Path Optimization

- No, as Design

- Select this option and the system will draw a process path according to the artwork. http://am.co.za/ If you need to change the output sequence by "Set Output Order" under Tool menu, you have to check this option.

- Yes, Optimize

- Select this option and the system will calculate the path according to the set requirements. http://am.co.za/ Optimized path has two options: Inner-to-Outer, Bottom-to-Up.

- Inner-to-Outer

- Process the inside of the object first and then the outline border. http://am.co.za/

- Bottom-to-Up

- You can set the size of "Block-on-Every". http://am.co.za/ The system will output from the bottom up according to the block height you set.

- Automatic Set Cutting

Direction http://am.co.za/ - If you check this option the system will set the cut direction automatically.

- Backlash Optimize

- If you select this option the system will set the cut direction automatically to compensate for any mechanical inverse backlash when cutting a sophisticated object. http://am.co.za/ But this will greatly increase the length of idle running. Usually this option need not be selected.

Delay with Laser Beam

- Delay Before/After http://am.co.za/

Laser On/Off - Set the delays in seconds (accurate to 1% of a second) http://am.co.za/ before or after the laser is on or off.

Output Solid Cutting Line as Dash Line

Just like Laser Perforating, the "cut dash line function" http://am.co.za/ will only partially cut the artwork out, the object with solid lines is processed to the effect of a broken line. http://am.co.za/ It's useful to make folding lines, tear lines and easy to break out objects.

- Cut Len

- Length of the cut line http://am.co.za/ (when the laser is on).

- Gap Len

- Length of the gap between the lines (when the laser is off http://am.co.za/).

- Gap in Front

- Define the first action to be a solid or broken line when the object with solid line is processed to the effect of a dash line.

Other Setting

- Corner Acceleration

- Define the normal acceleration of the curve in variable motion. http://am.co.za/

- Compensation on X/Y

- Backlash compensate the mechanical inverse gap by cutting with constant speed. http://am.co.za/

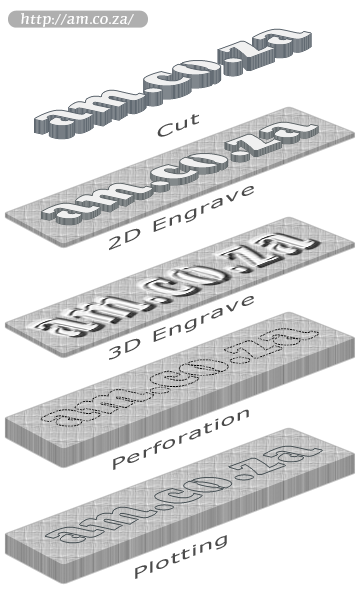

More Laser Process Methods:

![]() Cutting | 2D Engraving | 3D Engraving | Perforating | Plotting

Cutting | 2D Engraving | 3D Engraving | Perforating | Plotting

![]() Back CNC Laser Machines, Software Manual

Back CNC Laser Machines, Software Manual ![]() Next Chapter: Control Laser Machine

Next Chapter: Control Laser Machine

CO2 Laser Cutting & Engraving Machines For Sale

| SKU | CO2 CNC Laser Machine | Price | list,CO2_Laser |

|---|

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 2013/08/18 18:07 . [ Homepage | Price List | Visit Us ]