Laser Output Parameters in TruCUT Software

Laser process output options allow you to choose how many work pieces you would like to produce and how many delays you need to replace materials. http://am.co.za/ You can also run outlines to see if your artwork can fit into the material you have placed and also cut out your artwork by outlining it with border or borderless.

Since 2019, we have been using the TruCUT RDWorks system. Please check out the RDWorks Training VideosRDWorks Training Videos here. The following information is for software prior to 2019.

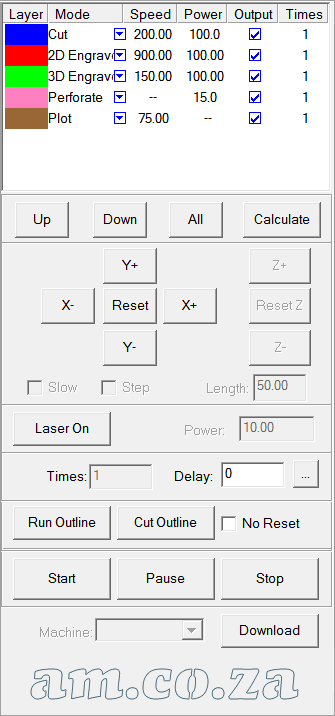

Setup Laser Process Output

Except for the fact that you can directly control the laser machine, http://am.co.za/ you can also set additional laser processing parameters for laser process output and perform laser output actions. http://am.co.za/ The panel for such settings and actions is:

These parameters and functions will only work after you connect the machine through a USB cable and the proper Laser Machine Driver has been installed.

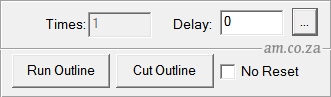

- Times & Delay

- The system will process "X Times" http://am.co.za/ of identical artworks with a "Y Seconds Delay" after each artwork is processed. http://am.co.za/ This delay time is for taking down finished work pieces and putting new materials. You can set them according to your needs. http://am.co.za/ This function will greatly increase the working efficiency.

- No Reset

- By default this option has not been selected, http://am.co.za/ which means the system will process the data according to its coordinates by resetting the laser nozzle to the starting point. http://am.co.za/ If you select this option, the system will process the data from where the laser nozzle is. http://am.co.za/ Relevant relations between the original point and the processing data remain unchanged.

- Run Outline

- After clicking this button, the laser nozzle will move in a rectangle with the laser off to allow you preview the laser process area, http://am.co.za/ so you can adjust your material(s) position. http://am.co.za/ Similar to "Test" button on the laser machine control panel.

- Cut Outline

- Click this button to cut the work piece off the material(s).

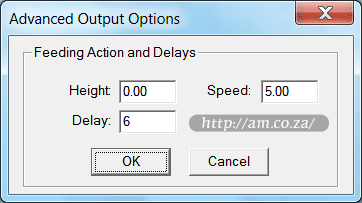

Advanced Feeding Solution

After you click the "..." button, http://am.co.za/ you can set the advanced output option for advanced feeding:

- Height

- After each processing, Z-Axis will lower a relevant distance defined by the "Height" http://am.co.za/ for the feeding of the materials.

- Speed

- Moving Speed of the Z-Axis.

- Delay

- The machine will delay a certain amount of seconds for feeding between each processing.

The advanced feeding feature is mainly for conjunction with automatic plate feeder. http://am.co.za/

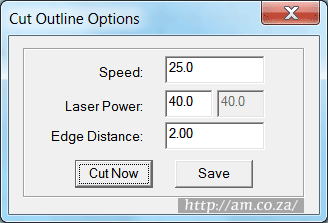

Laser Cut Outline Option

After you click "Cut Outline button, http://am.co.za/ you can set up the cut option when the dialog pops out as below:

- Speed

- Operating speed of the laser nozzle in cutting. http://am.co.za/ Different speeds can be set according to the material. It is better to define a proper speed through testing to make sure the material can be cut through.

- Laser Power

- Output laser power in cutting. http://am.co.za/ The second block will become editable if your machine contains two laser tubes.

- Edge Distance

- Distance between artwork and the cutting edge of the work piece that needs to be cut down.

- Cut Now

- Click the button and perform cutting action. http://am.co.za/

- Save

- Save the parameters for future use. http://am.co.za/

![]() Back CNC Laser Machines, Software Manual

Back CNC Laser Machines, Software Manual ![]() Next Chapter: Download Cutting File

Next Chapter: Download Cutting File

CO2 Laser Cutting & Engraving Machines For Sale

| SKU | CO2 Laser Cutter | Price | list,CO2_Laser |

|---|

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 2013/08/23 01:06 . [ Homepage | Price List | Visit Us ]