EasyRoute CNC Router Control Panel

Thank you for choosing EasyRoute CNC Routers. http://am.co.za/ This manual introduces the various functions of the system. Before using the CNC Router, Control Panel and related equipment, please read through this manual, http://am.co.za/ which will help you have a better use of the CNC Routing System.

EasyRoute CNC Router Hand-held Control Panel

EasyRoute CNC Router Control Panel has 128M internal memory, 256M flash memory and 128 × 64 graphic LCD display. http://am.co.za/ Before you start, please read these CNC Router and Control Panel basics.

- Internal Memory: 128M ( for operation, similar purpose as PC memory )

- Flash Memory: 256M ( for storage, similar purpose as PC hard disk drive )

- USB 2.0 Port: Support USB Flash Drive ( FAT32 Format, up to 32 GB )

Our panel is conformable to grab and easy to use, feel free to play around and recover to initial settings when needed.

CNC Router Basic Concepts | Control Panel Basic |

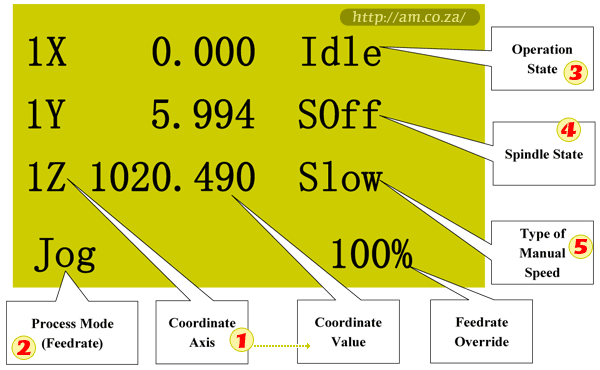

System Boot-Up Default Interface

After system boot-up, "Back to REF. Point" will be prompted firstly. http://am.co.za/ Press  to execute this operation.

to execute this operation.

The default mode after the system starts-up is the manual mode. http://am.co.za/ The processing page is the current page, including coordinate axis, coordinate value, operation state, spindle state, type of manual speed and processing mode.

Various operation prompts are displayed at the lowest part of processing page.

If the E-stop button is pressed during processing, http://am.co.za/ other buttons become invalid except the  button; you can press the

button; you can press the  button to modify contents.

button to modify contents.

1 Coordinate Axis & Value

The coordinate axis is comprised of Mechanical Coordinate System (MCS) http://am.co.za/ and Workpiece Coordinate System (WCS). http://am.co.za/ You can press the combination button  and

and  to switch between these two coordinate systems. "Processing Page" is WCS, and the number 1~6 http://am.co.za/ before X/Y/Z axis indicates the coordinate system from G54 to G59. http://am.co.za/ For MCS, there is no number before X/Y/Z axis. After returning to mechanical origin has been accomplished, http://am.co.za/ the sign of * will be displayed after the corresponding axis in MCS. Read More about Coordinate System.

to switch between these two coordinate systems. "Processing Page" is WCS, and the number 1~6 http://am.co.za/ before X/Y/Z axis indicates the coordinate system from G54 to G59. http://am.co.za/ For MCS, there is no number before X/Y/Z axis. After returning to mechanical origin has been accomplished, http://am.co.za/ the sign of * will be displayed after the corresponding axis in MCS. Read More about Coordinate System.

2 Process Mode

It is comprised of jog and stepping modes, http://am.co.za/ which can be switched by pressing the  button.

button.

3 Operation State

The operation state includes idle, E-stop, running, pause and lock states. http://am.co.za/ Read More about Operation, Modes and States.

4 Spindle State

It includes spindle gears and spindle stop which can be switched by pressing  under idle state. http://am.co.za/ During processing, press

under idle state. http://am.co.za/ During processing, press  +

+  or

or  +

+  to increase or decrease the spindle gear. http://am.co.za/ 1S represents rotate speed of the first gear, 2S rotate speed of the second gear, and nS rotate speed of the nth gear.

to increase or decrease the spindle gear. http://am.co.za/ 1S represents rotate speed of the first gear, 2S rotate speed of the second gear, and nS rotate speed of the nth gear.

5 Type of Manual Speed

Manual speed can be divided into two types: http://am.co.za/ manual high speed and manual low speed which can be switched by pressing  . http://am.co.za/ Please refer to Manual Processing Operation for the speed setting method.

. http://am.co.za/ Please refer to Manual Processing Operation for the speed setting method.

Menu Page

Menu Page

Press the menu button to enter the menu page. http://am.co.za/ There are altogether eight parameter items in the menu but the LCD can only show 4 of them at a time:

| 1. Local Files http://am.co.za/ |

| 2. USB Files http://am.co.za/ |

| 3. Operations http://am.co.za/ |

| 4. Oper Param http://am.co.za/ |

Press the  and

and  buttons to select the desired item and then press the

buttons to select the desired item and then press the  button to enter the corresponding sub-menu.

button to enter the corresponding sub-menu.

We will not give detailed guide to all menu functions here, since some functions are reserved for our technicians only. http://am.co.za/ If you have accidentally adjusted the settings when you play around, please recover all settings.

Processing Operation

Processing operations can be divided into two categories: http://am.co.za/ manual processing and automatic processing. Processing parameters and machining process can be adjusted conveniently in both manual processing and automatic processing.

Manual Tool Change

Our EasyRoute CNC Router series only support manual tool change, it allows multiple toolpaths with different tool which when the tool change command encountered, the panel will pause the process and prompt tool change. You need to manually change tool bit then press the button to carry on the process. The length of the tool needs to be manually measured and cope with your design.

Our EasyRoute CNC Router series only support manual tool change, it allows multiple toolpaths with different tool which when the tool change command encountered, the panel will pause the process and prompt tool change. You need to manually change tool bit then press the button to carry on the process. The length of the tool needs to be manually measured and cope with your design.

To get the supreme speed and convenience on Automatic Tool Change, please check our PowerRoute CNC Router series.

EasyRoute Control System and Keypad

| SKU | EasyRoute Control System Replacement & Spare Parts | Price | list,r_keypad,r_panel |

|---|

EasyRoute Series CNC Router For Sale

| SKU | EasyRoute CNC Router Series, Standard 3-Axis CNC Router | Price | list,Router_3 |

|---|

Because of the continuous updating of hardware and software, http://am.co.za/ the EasyRoute CNC Router and Control Panel you bought may differ from this manual, we may have a side-note on the difference for your year model.

# EasyRoute Control Panel is based on http://am.co.za/ Weihong NK105 CNC Integrated Machine OEM with customized machine settings pre-loaded for our EasyRoute CNC Routing machines. http://am.co.za/ EasyRoute Control Panel is backwards compatible with Weihong NK105 CNC Motion Controller system when reset to initial states with no pre-loaded data. Download Weihong NK105 Manufacturers' Manual.

© Bates Trust, Advanced Machinery ™

http://am.co.za/ . 2013/10/02 00:11 . [ Homepage | Price List | Visit Us ]